Share

Residents near a northwest Fresno elementary school have been waiting for the traffic signals to be turned on for a while.

The poles were up, but the lights remained wrapped.

“It’s very frustrating. I’ve been waiting for a year. They’ve been waiting for a year. The principal (of Starr Elementary) Charlie Reynolds, great guy, he’s been waiting for a year. But we’re about to get done finally,” Fresno City Councilman Mike Karbassi said.

It was an odd sight at the corner of Sierra and West avenues, where the new traffic lights — with an added signal for a dedicated left-hand turn lane — were feet away from the exiting light.

Karbassi said a demand for safety by the school prompted the lights that have been in the city budget for three years. Various problems have caused delays.

“It’s taken time with the pandemic to get to get the contract approved and and get a contractor out here. We’ve done that. But we’ve also dealt with record supply chain issues, where not just the poles, but the cabinet and that semiconductor, the chip hardware took over a year to get it stocked. That’s why this intersection … looks like it’s complete, but it’s not,” Karbassi said.

Finally, on Monday, the lights were turned on. The old poles will be removed shortly.

Controllers are inside the box on the side of the road that act as the “brains” for the traffic signal. Finding controllers in stock is sometimes — as in the case for the Starr Elementary traffic signal — the reason for the delay. The costs stretch into the six-figures.

Installing and paying for lights is sometimes the responsibility of the government agency. For newer neighborhoods, lights are installed by the developer as a condition of approval.

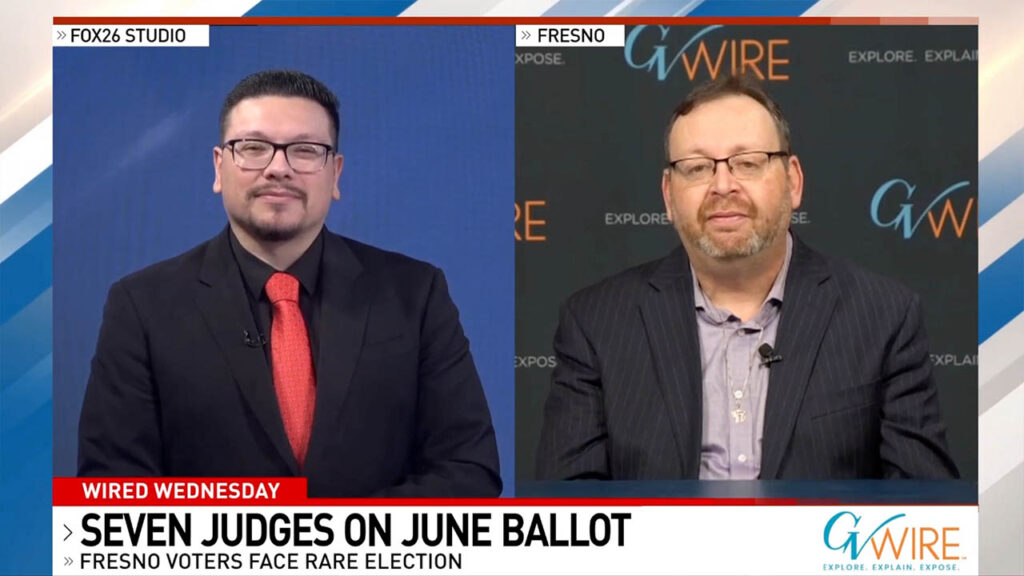

The problems with the northwest Fresno traffic lights are not unique. Several cities, including Clovis, have experienced problems installing lights in a timely manner.

“The time to build it is really dependent upon getting the parts and the the availability of that timeline has gotten longer over the past couple of years, but we still managed to deliver the project on time. So we’re finding a way through the difficulties that we’re facing,” Sean Smith, supervising engineer for Clovis, said.

Traffic signal poles, Smith said, can take up to 12 months to order. The control boxes are taking about six months to arrive. The cost per signal in Clovis is $400,000.

Clovis has about 10 signals either under design or under construction. The city says it has no priority as to which gets built first but factors in availability of funds, safety concerns, and whether developers may install signals ahead of the city.

Other Lights Have a Slow Roll

GV Wire spotted several projects around Fresno at various waiting points.

At the corner of Temperance and Dakota avenues in east central Fresno, traffic light polls are stored next to a sidewalk. It has been that way for months.

Poles are next Traffic light poles lay on a sidewalk at Temperance and Dakota avenues. (GV Wire/David Taub)

Poles are next Traffic light poles lay on a sidewalk at Temperance and Dakota avenues. (GV Wire/David Taub)

Another traffic light is installed, but yet to be turned on at Armstrong and Clinton avenues.

The councilman for the area, Nelson Esparza, said the city is in the final stages of giving approval.

A traffic light has been installed at Palm and Dennett avenues near Muir Elementary in central Fresno, but still not operational. Earlier this week, construction workers were busy. The equipment has been up since at least August, one passerby said.

And, the lights recently turned on at Olive and Armstrong near Temperance-Kutner Elementary School, months after they were first installed.

Esparza is trying to remain patient, understanding that projects are “still feeling the residual impacts of this post-COVID economy.”

“It really is not surprising when you dig into one of these projects and find that there’s a delay because of X part has not come in or we haven’t had the workers available,” Esparza said.

Work is now starting on a traffic light at Audubon Drive and Del Mar Avenue, near the San Joaquin River Trail in north Fresno. The cost is $1 million, although that includes striping and curb work.

“Now what we do is we now order early and keep a healthy stock. We learn so that the next time we plan these things, we don’t have a situation like this happening again,” Karbassi said.

Karbassi said the city is improving ordering early to prevent delays.

Fresno Signal Maker: More Than One Issue

Traffic Signal Hardware, located north of Fresno Yosemite International airport, makes traffic mounting hardware — one of several pieces that go into making a traffic signal.

“It’s something you never look at, but you look at it all the time. So between the LEDs, the signal and the big mounting poles, we make the little junction boxes and mounting hardware that does that gap,” said Kevin Tolman, owner of Traffic Signal Hardware.

The company mainly sells its parts to distributors, who put together the lights and sell them to government entities, such as Fresno and Clovis.

Ordering parts in advance can be easier said than done.

“We don’t make it until somebody orders it. And so because of that, it takes a long time to be made. Our lead times are typically from the time someone places it four to six weeks. But our fittings, the castings and whatnot, we’ve placed orders in six months in advance to fill that order in 4 to 6 weeks,” Tolman said.

Tolman gets his materials from metal foundries located in the Central Valley.

“A lot of their problems right now is labor. They’re having a hard time filling positions to pour metal,” Tolman said. Waits have nearly quadrupled since the pandemic.

Smith, the Clovis traffic engineer, said there is no one part that is causing delays.

“The cabinet, the poles, all of them have experienced extended lead times over the past several years,” Smith said. “The developers have done a very good job at knowing what the critical times are, preplanning their jobs, ordering them ahead so that when they’re ready to complete the project, the signal is also ready to be finished at the same time.”

Federal spending regulations also play a role in the price and time it takes to produce, Tolman said. Projects that receive federal dollars require iron made in America, increasing the price. Poles cost up to $60,000.

The summer is usually Traffic Signal Hardware’s busy time. Tolman said they can be backed up six months.

“Our slow time is usually November, December. There’s not too many projects going on. And so we’re actually I would say we’re caught up with our work,” Tolman said.

RELATED TOPICS:

Categories

Hey Ilia, America Is Still Proud of You.